|

December 27, 2008. Your webmaster has been working, on and off, on a Dolphin Mast Page for months - I have been thinking about a new mast for Marionette for years. Lets start with this tidbit of information. My main contact at S&S, Harry Morgan, started with them as a mast designer. He tells me that S&S had a well deserved reputation for designing 'bridge breaker' masts. This term, perhaps a bit overstated, describes the S&S specified mast of the 50's as being conservative, heavier and stronger than perhaps necessary in the view of some. S&S prided itself on designing boats that would not have design and construction failures and breakdowns on offshore voyages.

The inevitable consequence is that, over the years of its production, Dolphin builders and individual owners often used lighter section masts for both cost and performance reasons. The early Dolphins had in line single lower shrouds so concepts like using mast bend in determining sail shape were problematic. Telephone poles do not bend - much. Later Yankee and Pacific built boats has double lower shrouds so still lighter mast sections and mast induced mainsail shape became more possible.

|

Both aesthetics and technology influence the possibilities for a Dolphin mast. John Shumaker, founder of Yankee Yachts, built his first Dolphin in 1964/65, Yankee # 71, with a wood mast. She is still sailing as Charlie Street's Arion, (left) and she still has her original spruce mast.

Today, you can get a much lighter carbon fiber mast, painted to look like wood, and get much lighter weight, and both improved performance and if faux painted, almost get that special wood look.

And you can get a epoxy wood strip, hollow wood mast that will knock your socks off as well as your bank account. Aluminum mast technology has also evolved - you can get a variable section thickness mast that is lighter but keeps the strength you need where you need it. And you can get this mast, or any aluminum mast, faux wood grain painted as well.

|

So, what to do. What follows will not answer the question but will, hopefully add to the knowledge base. There are many variables but final cost is always, or almost always at the forefront. This makes a modern wood mast, and a carbon mast, at the outside edge of what most Dolphin owners think reasonable. Nevertheless, we do want to know what and where these outside edges are. Your webmaster undertook to find this out for Marionette.

Plan A The Wood Mast

I sent the following information to a couple of well known wood mast builders. I left off their names but if anyone would like to contact them I will provide contact info.

Email to 2 wood mast builders in 2007

I have a 46 yr old Dolphin 24 (Marionette) which I restored myself. I race her occasionally and cruise it single handed. I am thinking about a new mast, and maybe a new boom and spin pole. The boat is a masthead rig and the mast is deckstepped. The mast is 29' 7" and is a 5" (5 1/2" with luff groove) x 3.5" straight section, 1/8" thick aluminum. The extrusion only, per the technical specs, weighs about 66lbs. All up with standing rigging (6 ss, upper/lower in line, forestay, bronze turnbuckles and bronze adjustable backstay fitting (no halyards), alum spreaders and fixed mast hardware, including a single halyard winch, a radio wire, no electric wire, it weighs 107 lbs.

I am considering a wooden mast but instead of a buff painted alum mast replacement I'd like to find out what a modern

construction hollow mast and boom system would cost and what the weight difference would be. The boom is aluminum, 3 3/4" x 2 1/4 ", 12' long including gooseneck/track fitting. The extrusion itself is 11'9" long. It isset up with internal outhaul system and fittings for 2 reef points. The Spin pole is alum, 2" in dia and 8'11" long, from outside edge of the fittings. The spreaders are 1/16" thick aluminum, airfoil shaped tubes, 2 3/4" x 1 1/2" at the mast, tapering to a 1 1/8" round shroud end, 2' 6 1/2" long. They weigh 1.5 lbs ea. - pretty nice I think, and maybe could be painted.

******************************

Reply #1

Ron,

I have just had a chance to look into a wooden mast for your Dolphin. A approximate price for a box section mast is $8,500. The price for the boom will depend on the hardware that you are going to use. Let's assume a starting price of $1,900 which includes the construction of the spar and installation of typical hardware. The spinnaker pole will run about $850. Before putting too much time into this endeavor, I did a quick design for the mast and a weight analysis to get an approximate weight for a new mast. For a wooden mast to have the same strength as your aluminum mast, it would have to be a larger box section.

I estimate that a new mast would need to be about 4 1/2" x 7 3/4" at the base and taper to 3 1/4" x 3" at the top. The taper would not be uniform, so the average dimension would be 4" x 6 1/2". This would mean that the mast would weigh somewhere in the neighborhood of 100 - 115 lbs. Sitka Spruce weighs about 27lbs / cubic foot. Your new mast would have a volume of 3.3 cubic feet, giving a wood weight of about 90 lbs. Plus the weight of the epoxy glue and bronze tangs for shroud connections.

I do not pretend to be a naval architect, but I am confident that a traditional box section style mast will weigh more than an aluminum mast. The other types of wooden mast construction, including eight staved and cold molded, would come closer to the weight of your aluminum par, but the cost would be much higher. An eight staved mast would be round or oval and could be comparable in weight to your aluminum spar.

Cold molded would probably weigh much less than other wood masts, and less than your aluminum spar, but the cost increase would be double or triple the other techniques. Finally, I would want a naval architect to double check any mast that I designed to ensure that the strength would be adequate. This will also have a significant cost.

Let me know if you would like to proceed with a more detailed quote for any of the afore mentioned options.

************************

Reply #2

Ron,

Thanks for the picture. I think a wood mast and boom would be fabulous. I am biased, however, being a spar maker. Right off the bat, a wooden mast, hollow or not, is going to be heavier. How much, I can't say without doing some calculations. What I can say is that dimensionally, everything will have to change. Typically, aluminum spars are smaller than wooden ones because of the material characteristics. So my first question to you is: are you prepared to go to that extreme?

Our cost for a box section wood mast is $110.00/Lft not including the mast head, sheave box, tangs, through bolts. We bill mast head construction out on a per hour basis. It can take from 8-12 hours to fabricate the mast head. The mast will cost $3245.00 and the mast head could run from $720.00 to $1080.00. That does not include hardware. We will have to factor in the sheave box, which I will assume we can't take from the old mast, and any other hardware that can't be transferred. A sheave box costs ~$500. Tangs can cost $300-400. Then there are spreaders ($500.00), their hardware, stays, etc. Winches have to be transferred. What about the luff? You should probably switch to track which will mean looking at your sail to see if that's ok to do.

The boom is obviously less costly, but I will have to figure out the right dimension, as the same applies to the other spars (aluminum vs wood). The boom only will cost ~ $750.00. I am estimating these two spars in Sitka Spruce. Vertical Grain Douglas fir will weight twice as much, and I don't think you can afford that. The hardware on the boom will need to be replaced or re-fitted.

Finally, not to burst your bubble, but there will be some design time on top of all the other charges, and the pole is delivered with one coat of marine grade sealer, unless you want us to varnish it. You could easily be looking at $6500-7000.00 for the mast and boom.

Let me know if I haven't addressed all your concerns and questions.

*********************************

Bottom line Wood Mast - a beautiful wood mast, whatever construction, will be heavier and a conversion will cost minimum $8,000-$12,000. I thanked both mast builders for their time and information and went to Plan B

Plan B - A Carbon Fiber Mast

The same basic request for information letter above was sent to 2 carbon mast builders, one a very busy leader in this field, the other less well known. These are their replies.

Reply #1

Hi Ron,

Sorry for the delay in getting back to you. I wanted to ballpark a couple of things for you to see if it all makes sense. I think the mast price would be around $13,000.00. This would be in carbon with spreader and all the necessary hardware. I think the weight would be between 30-40% less. The other side of going to carbon is that the mast will be much stiffer both fore and aft and side to side. We could do a carbon boom for around $1,600.00, the weight savings won’t be a ton, but it will look the part quite nicely. We can duplicate the existing wire setup or switch to rod. I think form the PHRF side of things you will be looking at between 3-6 secs per mile depending. I know for PHRF NE the rating change form Aluminum to Carbon is 3-6 (sec/mile). I would consult your local fleet to narrow down the hit. If this works for you I can work on a formal quote. The other big question is what is your delivery time frame?

Please let me know.

*************************

Reply #2

Carbon mast $2,838.00; carbon spreader brackets 2@$156.00; carbon boom $630.00; goose neck, mast bracket, toggle $135.00; Boom Clutch plate and install $235.00; Track install allowance $ 210.00 Spreader brackets 2@ $35.00; Backing plates and dry fit $200.00; Composite mast head and Harken 311 HL sheave and single aft pin for back stay $250.00; Forestay/twin jib H fitting and dry fit $250.00; Spin ins $195.00; Double in for spin a h's over under Harken 288's dry fit $90.00; Topping Al in box for Pole up and dry fit $45.00; Carbon spreaders with ends $ 216.00; Spreader install $ 550.00; Ronstan 19mm track system $383.00; Sand spar (all surfaces to 120 grt) $325.00; Boom tail end including 3 HL Ronstan stand ups for OH and 2 reefs $235.00; Cut exit slots (5) $175.00; Harken track on front of spar allowance for part and install $165.00; Crating Freight & Handling $85.00; Motor Freight & Handling $220;

Total $7650 (does not include faux painting -est $1500)

*******************************

Bottom Line Carbon Mast - estimated weight savings about 35lbs; $9000 to 13,000+. I thanked both mast builders for their time and information and went to Plan C

*******************************

Plan C The Aluminum Mast

Your webmaster has been working on this. Erik Evens' post of Dec 23, 2008 on the Forum has been the motivation to get this page up. Hopefully, we will get more imput, and reality. Generally speaking, it seems one wants the lightest mast that can carry the loads anticipated without deforming to the point of failure. In your webmaster,s internet research there were several short, reader friendly articles/forums/etc. that shed light on the complex issues involved in mast design. Some of them are compiled on a separate page and will be added to as new interesting items are surfaced. Click to go to that page

Now that we have done a little homework it seems we are ready to look at 3 aluminum mast options, maybe 4

1) Duplicate in aluminum exactly the mast you already have, new everything, including standing rigging. Deliver the old mast to the mast builder - a no hassle, no worry, turnkey approach. There seem to be several different masts in our universe of Dolphins so if your old mast worked for you for 30-40 years no need to waste valuable time looking at what everyboby else has..No bragging rights accrue.

2) Buy a new straight section extrusion exactly like the one you already have and move all the fittings and rigging possible from the old mast to the new mast. This could be done by the owner, is probably the least expensive approach and allows the future offhand comment by the owner "Oh, the mast? Well, I built 'er myself"

3) Evaluate, with the help of a mast builder and/or a marine architect, a new lighter extrusion, or the variable section thickness extrusions available; consider the plus/minus issues of a tapered section at the top third of the mast ($ vs weight saving aloft including buying a new masthead fitting) evaluate the running rigging, spreaders, brackets and other fittings you have for possible use in your new mast;

Reducing weight aloft alone is a worthy goal. Beyond that evaluate with the help of your sailmaker the potential for performance improvements with new sails designed for a more flexible, and tune-able mast - and get an estimate of the cost of a new mainsail to take advantage of high performance potential (be careful, selectors of this option will be noted as potential future webmaster material)

4) Unless a mast is badly bent, or corroded in critical areas, they are pretty durable. You can defer, delay, procrastinate, gather additional information, ignore, repair, fix, baby, paint?

We do have some information on these options but need more. Your webmaster just happens to know Bob Dwyer, owner of Dywer Aluminum Mast Co http://www.dwyermast.com/. Back in early 1960's we were on the same bowling team - Mike's Bar and Grill.... So, back in December of 2007 we had a conversation about Dolphin masts.

Marionette's mast is an oval section 5.5" x 3.5" x .130" that I cannot find in either Dwyer's online catalogue or RigRite/Kenyon's. Dwyer's closest equivalent is DM500 5.0 x 3.5 x .130. http://www.dwyermast.com/items.asp?cat1ID=20&cat1Name=Masts&familyID=43&familyName=DM%2D500+Mast Dwyer

Kenyon's equivalent mast has the same dimensions as Dwyer's - and they list the Dolphin as a user of this mast section. Here is the link .http://www.rigrite.com/Spars/kenyon_spars/3550-Mast.html.

It is interesting to note that the moments of inertia values for these 2 masts are different, based on the values given in their respective tables.

| specification |

Kenyon |

Dwyer |

Dwyer |

Marionette |

| section #/ID # |

3550 |

DM500 |

DM330 |

? |

| outside dimensions |

5.00x3.50 |

5.00x3.50 |

5.00x3.30 |

5.5X3.5 |

| material thickness |

0.13 |

0.13 |

.13/.09 |

0.13 |

| weight lbs/ft |

2.2 |

2.2 |

1.65 |

2.31est |

| extrusion wt/lbs for a 29'7" mast |

64.9 |

64.9 |

48.7 |

68.1est |

| moment of inertia Ixx (fore/aft) |

5.5 |

4.81 |

4.62 |

? |

| moment of inertia Iyy (side to side) |

2.7 |

2.55 |

1.97 |

? |

| cost/ft |

? |

36 |

27.85 |

0 |

| stocked length in ft |

? |

32 |

33.50 |

na |

| cost of extrusion |

? |

1221 |

989 |

0!! |

|

First, Bob and I discussed his DM500 section. My mast oval is not exactly the DM500 section but similar. It has the mast track 'molded' on what would otherwise be a DM500 section, adding about 3/4 " to the longer "I" dimension.

The DM 550 has the mast track molded inside the 5" dimension. I wondered if this is an important difference. I was told the inner molded track was favored because it kept the luff of the sail closer to the bulk of the mast. Also, my mast would be stiffer fore and aft (Iyy), and a bit heavier.

|

|

He said he would recommend I go to their section DM330 which has a variable material thickness between .9 and .13 across the section, putting the extra thickness where needed and thinner material where not. The section weight is 1.65lbs/ft, and the oval shape dimensions are 3.3" x 5". This section also has an intermal mast track, using round cylindrical slugs instead of rectangular slides as I have now.

Also, there is a tiny extruded profile inside the mast. This allows a plastic sleeve to be inserted in the mast into which electrical and antenna wires can be placed preventing the banging and slapping that can be annoying.

The difference is .55lbs/ft, a 25% savings. On a 29''7" mast the weight savings is just over 16 lbs on the extrusion section alone.

|

He said he would recommend I go to their section DM330 which has a variable material thickness between .9 and .13 across the section, putting the extra thickness where needed and thinner material where not. The section weight is 1.65lbs/ft, and the oval shape dimensions are 3.3" x 5". This section also has an intermal mast track, using round cylindrical slugs instead of rectangular slides as I have now. Also, there is a tiny extruded profile inside the mast. This allows a plastic sleeve to be inserted in the mast into which electrical and antenna wires can be placed preventing the banging and slapping that can be annoying.

The difference is .55lbs/ft, a 25% savings. On a 29''7" mast the weight savings is just over 16 lbs on the extrusion section alone.

Looks good to me. But, before I do this, if I do this, maybe I need to check out the moment of interia differences with S&S (Harry Morgan)?

|

NOTE: The original plans show the upper shrouds terminating very near the top of the mast - that bolt just under the masthead cap fitting in the picture at left. My uppers terminate 6'" below the top of the mast and somewhere I have notes that the uppers could terminate as much as 20 inches below the top of the mast. The difference is a savings of 12 inches extra 3/16 ss wire; 40 inches if your particular rig has shrouds to the top of he mast. The offset is an additional through bolt to secure the tangs, needed in Marionette's case as the tang bolt and the sheaves bolt are the same - but I could gain 28" less wire. Ok, not much weight, a few ounces but they are at the end on a 30' lever...

|

My spreaders are 30 3/4 inches long whereas the original drawings call for 34 in long. So some 'alteration' work has been done already! I will have to dust off my cadcam system and see what the length should be and still maintain the proper spreader angle (spec calls for 11 degrees) if I drop the tang another 14 inches. Of course, Harry will have to tell me what is lost when the spreader length gets changed

Of further interest is tapering the mast at the top. This costs about $300 to do, according to Bob, and may mean some additional gratis marine architect consultations. About 10' would be tapered and might save an additional 5-6 lbs? A new mashead fitting (smaller), sheaves, etc would be required.

Bottom Line? If Harry will let me use it a Dwyer stock length DM 330 extrusion is 33' 6" and the cost is $27.85 ft = $933. Cut exactly to length incurrs a $10 cutting charge, plus 6% for the Governor = $988.95 loaded on the roof rack of my wagon for the 25 mile trip home. All this puts a new aluminum mast in the realty game. I can build it myself according to my own timetable and just use the old one as a model for exact location/placement of fittings. Then, next winter I can remove the old fittings and mount them on the new extrusion.

Lets say $1000 plus 20% for unanticipated new parts - $1200. No new standing rigging - I think Marionette's shrouds and turnbuckles are excellent shape, thanks to gallons of WD 40 over the years. I save maybe 20-22lbs, plus I no longer have to look at that little kink in my present mast about 8' from the top (was there when I got the boat) and I don't have to worry about those little corrosion? spots on either side of mast at the spreader brackets.

If Harry say no, then stick with what has worked for 48 years and don't worry about the bridges. The DM500 option will cost about $250 more - $1450 and I might save 5lbs. Either way I get bragging rights - "I built that mast"

In the meantime, I am in option 4) mode above.

***************************

For more information on a the weight of a fully rigged mast, click here.

************

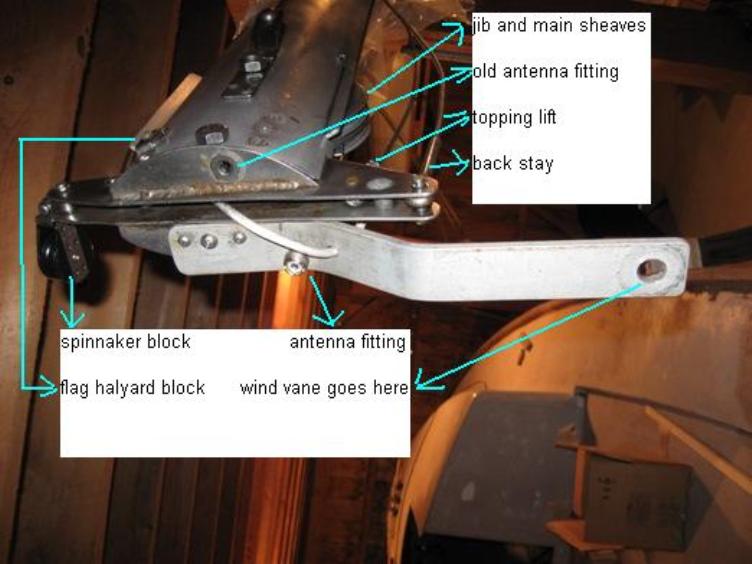

August 12, 2012. Clinton Hodges, Yankee #245, Windswept Too, raised a question about the topping lift connection to the masthead fitting. This seemed like a good excuse for the following picture of Marionette's set up.

To be continued

|